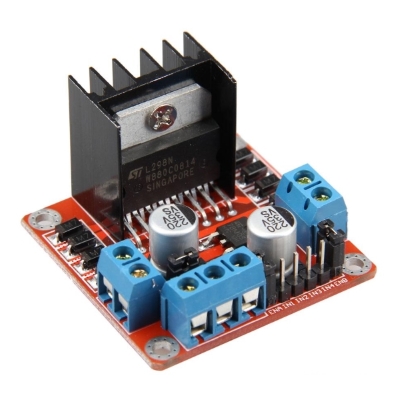

The armature is connected to a DC power source using a 2-piece ring installed around the motor shaft, these ring sections are called “commutator rings”. The armature, which is the rotating part, is a simple coil. The stator is a permanent magnet and provides a constant magnetic field. In a simple DC motor there are two main components, the “stator” and the “armature”. Today we’ll examine a very common H-Bridge module based around the L298N integrated circuit. An “H-Bridge” is an arrangement of transistors that allow you to control both the direction and speed of the motor. A single transistor can be used to drive a DC motor, this works well providing you do not need to change the direction that the motor is spinning.Ī more versatile way of controlling a DC motor is to use a circuit called an “H-Bridge”. There are a number of ways to drive a DC motor from the output of your computing device. It is necessary to use some external electronics to drive and control the motor, and you’ll probably need a separate power supply as well. DC motors have current and voltage requirements that are beyond the capabilities of your microcontroller or microcomputer. Unlike LED’s you can’t just connect a DC motor to one of the output pins of your Arduino or Raspberry Pi and expect it to work. They are inexpensive and are ideal for use in your Robotics, Quadcopter, and Internet of Things projects. Today DC motors range from huge models used in industrial equipment to tiny devices that can fit in the palm of your hand.

Since then DC motors have been part of countless pieces of equipment and machinery. The first practical DC (Direct Current) motor was invented by the British scientist William Sturgeon in 1832.

0 kommentar(er)

0 kommentar(er)